Most teams discover coordination gaps during a live peak shift, not from RFP spreadsheets. Working across different tech companies, I have seen robot traffic rules clash with WMS wave releases, human pick rates, and safety stop recoveries when orchestration is a bolt-on. From my experience in the startup ecosystem, the winning setups standardize task APIs, simulate multi-robot traffic, and tune recovery routines for aisle blockages. The backdrop matters too - the mobile robot market reached roughly 4.5 billion dollars in 2023 and was forecast to hit 5.6 billion dollars in 2024, a pace analysts still describe as robust despite regional slowdowns, per Interact Analysis' latest view of AMRs. That context frames why smart "Autonomous Robotics Workflow Tools" are now a C-suite topic. (Interact Analysis)

You will learn which platform fits your use case, how they differ on fleet control and simulation, what to expect in pricing models, and the traps that lead to stranded robots. As a market reference, IFR reported 542,000 industrial robot installations in 2024 with 4.66 million robots in operation, which amplifies the need for orchestration software that coordinates people, robots, and systems in real time. (IFR via The Robot Report)

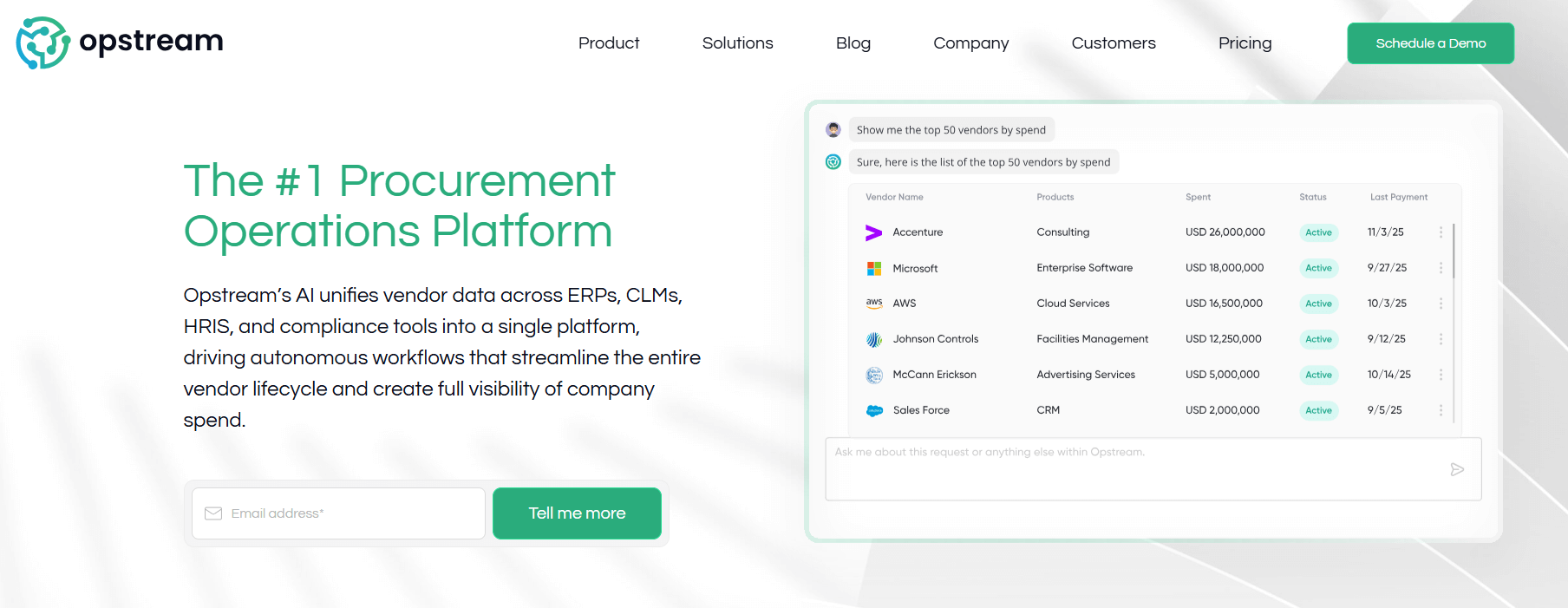

Opstream

AI-powered no-code platform for autonomous, policy-aware business workflows that react to live data. Positioned to coordinate cross-system procurement, finance, and compliance processes that often gate floor automation.

Best for: Ops and IT teams that need an autonomous approval and compliance layer to trigger robot work orders, WMS tasks, or facility tickets only when policies and budgets are satisfied.

Key Features:

- AI-generated workflows that adapt to live data and policy changes, per vendor documentation.

- No-code editor for routing, conditions, and approvals.

- Policy enforcement and audit trails built in.

- Integrations spanning SSO, e-signature, ERP, ticketing, and vendor risk tools, per vendor documentation.

Why we like it: It reduces human "chase work" that commonly delays material moves, so robots are dispatched only when prerequisites are met, cutting rework at the dock.

Notable Limitations:

- Younger product, reviewers note edge cases may need vendor collaboration to address. See sentiments in recent user feedback on G2.

- Reviewers also call out analytics depth as an area for improvement, again echoed on G2.

Pricing: Pricing not publicly available. Per the product listing, the vendor does not post list pricing on G2. Contact Opstream for a custom quote.

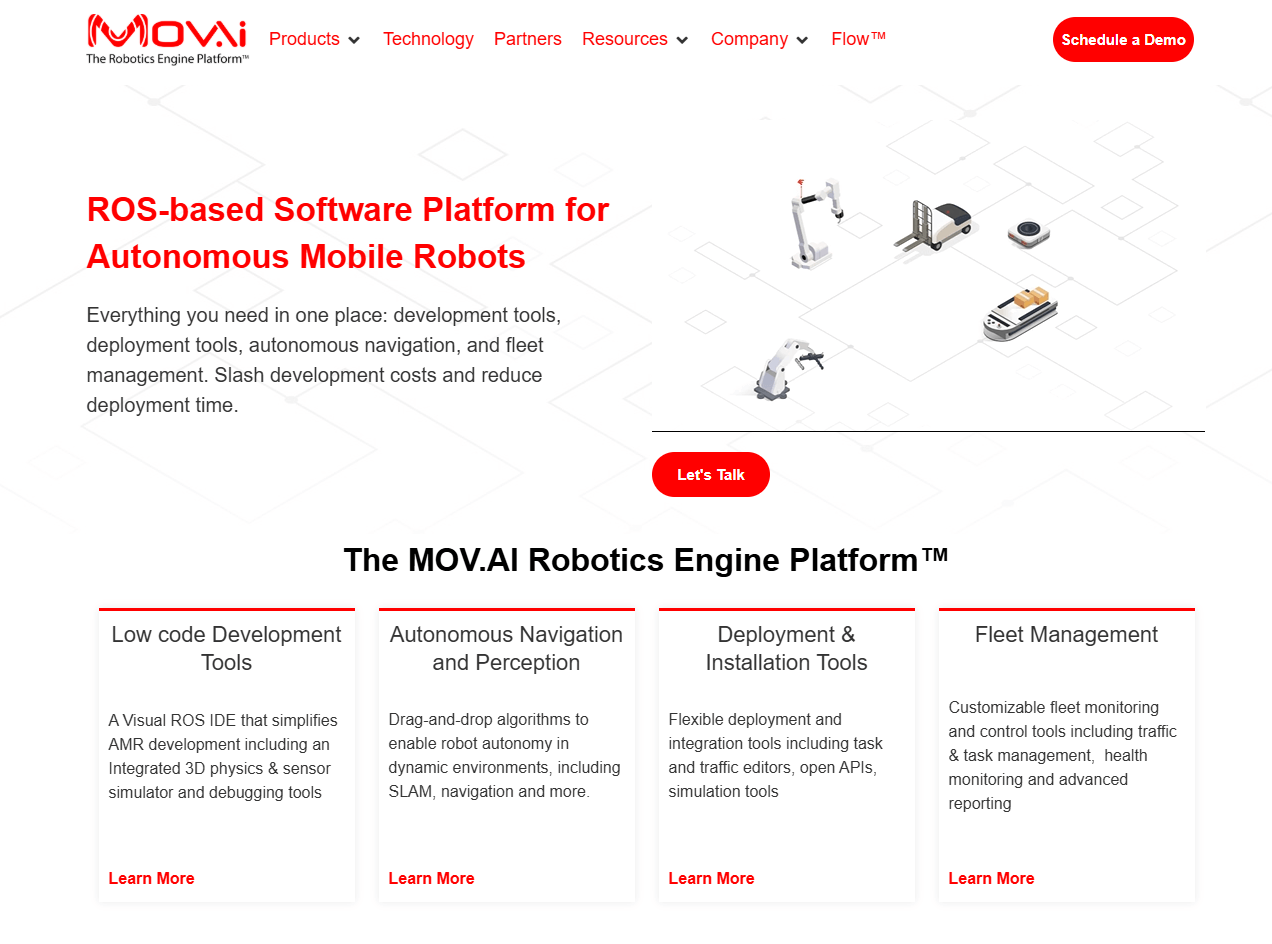

MOV.AI Robotics Engine Platform

ROS-based platform that combines a visual IDE, 3D simulation, autonomy blocks, and fleet management to speed AMR development and deployment. Suited to teams building or customizing AMRs.

Best for: Robot OEMs and system integrators who want low-code ROS development, built-in simulation, and enterprise features like versioning, CI/CD, and security.

Key Features:

- Visual ROS IDE with 3D physics and sensor simulation, plus debugging tools, per vendor documentation and a public release announcement on PR Newswire.

- Navigation, localization, SLAM, and pallet perception modules packaged for dynamic environments, described in product releases summarized by industry newswires.

- Open plugin framework and APIs to integrate third-party algorithms and drivers, per vendor documentation.

- Cybersecurity measures across the stack, highlighted in version updates covered by tech newswires.

Why we like it: The integrated simulator and visual tooling can collapse bring-up time, which saves both bench hours and floor disruption during pilots.

Notable Limitations:

- Deep customization still benefits from ROS expertise. Academic and industry surveys note ROS' learning curve and real-time constraints in multi-robot deployments. See a 2024-2025 community study on ROS 2 adoption in the International Journal of Intelligent Robotics and Applications and a 2024 arXiv paper that explicitly calls out the usability gap addressed by custom GUIs. (SpringerOpen study, arXiv UI paper)

- Public third-party product reviews remain limited compared to larger AMR suites, so plan a tightly scoped pilot and reference checks.

Pricing: Pricing not publicly available. Contact MOV.AI for a custom quote.

Vecna Robotics Pivotal Orchestration Engine

Orchestration suite that coordinates AMRs, workers, and WMS to optimize pallet and case workflows, backed by a 24x7 command center for remote monitoring and teleoperation.

Best for: Warehousing and 3PL teams focused on pallet or case movement who want human-robot coordination, WMS integrations, and outcome-oriented SLAs.

Key Features:

- Real-time task assignment and dynamic re-routing, plus integrations with leading WMS platforms, as highlighted in third-party funding and product news. (Business Wire funding brief)

- Pivotal Command Center for remote monitoring, issue resolution, and teleoperation to maintain uptime. (Business Wire overview)

- Proven case picking orchestration, with CaseFlow coordinating robots and human pickers to automate most travel, reported to double worker throughput in field pilots. (Business Wire product launch)

Why we like it: The human-in-the-loop command center and workflow focus reduce "robot wrangling," which is where many ROI models leak.

Notable Limitations:

- Optimized for Vecna robots and material handling workflows. Multi-vendor orchestration may require an interoperability layer based on industry standards that the broader ecosystem is advancing, such as the MassRobotics AMR Interoperability Standard. (MassRobotics explainer)

- No public price list. Buyers report subscription and SLA structures rather than simple license fees, common in modern AMR programs.

Pricing: Vecna frequently positions Robots as a Service with SLA backed operations in third-party materials. Expect custom quotes and subscription models. (3PL and pricing model page, summarized in media, Business Wire product launch)

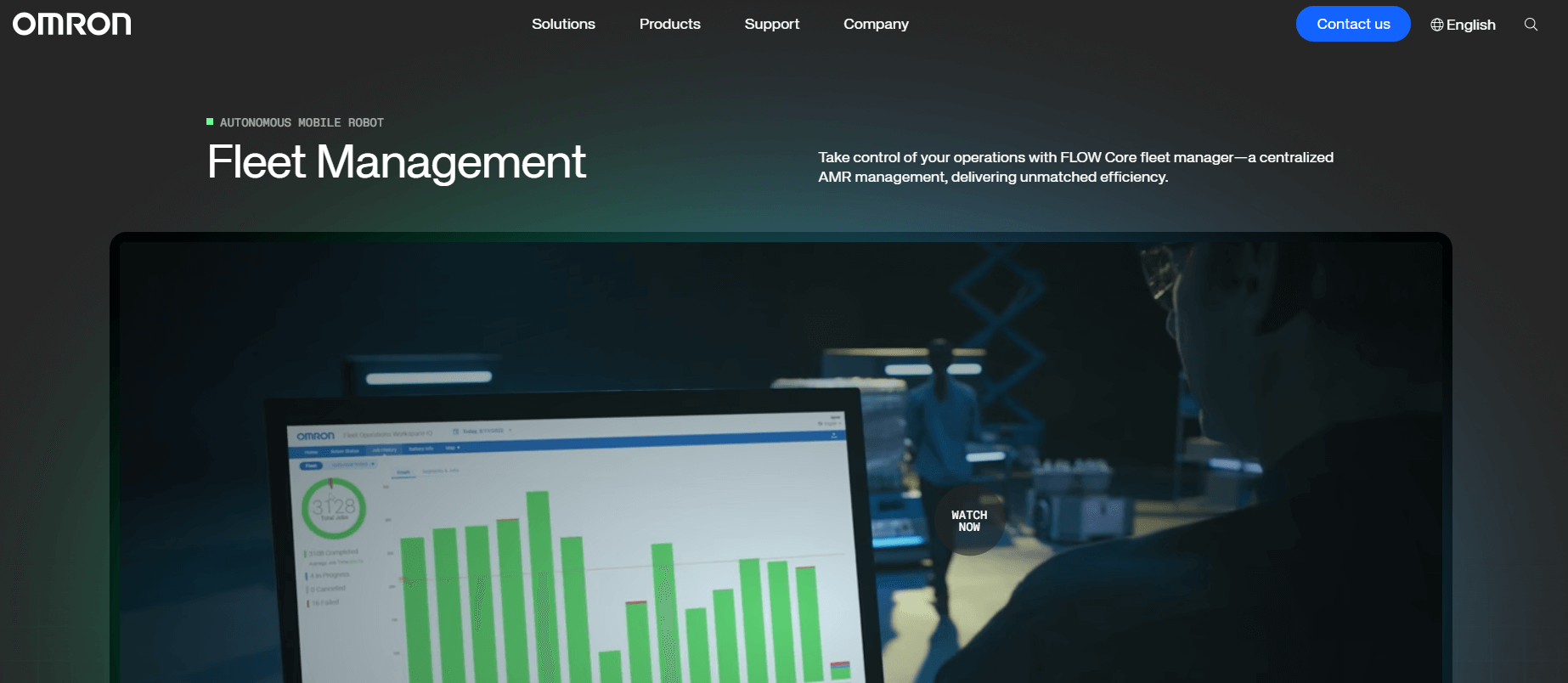

FLOW Core by OMRON

Centralized fleet management for OMRON AMRs with intelligent tasking, traffic control, analytics, and a simulator to de-risk deployments.

Best for: Manufacturers standardizing on OMRON AMRs who want one console for job assignment, traffic rules, charging strategy, analytics, and pre-deployment simulation.

Key Features:

- Centralized job assignment and dynamic traffic control across an OMRON AMR fleet, per vendor documentation.

- FLOW iQ analytics for heat maps, bottleneck analysis, and battery health, described in public product news items.

- Fleet Simulator to test workflows before go-live, reported by regional OMRON news pages and distributors.

- MobilePlanner app for live monitoring and control, per training and product materials.

Why we like it: Having a simulator and analytics tied directly to the fleet manager cuts trial time and catches wireless, map, and traffic issues before they bite throughput.

Notable Limitations:

- Primarily designed for OMRON AMRs. Mixed fleets often rely on emerging interoperability standards or third-party layers, as highlighted by the industry's push behind the MassRobotics AMR Interoperability Standard and VDA 5050. (MassRobotics overview, The Robot Report standard coverage)

Pricing: Pricing not publicly available. Contact OMRON or an authorized distributor for a custom quote.

Autonomous Robotics Workflow Tools Comparison: Quick Overview

| Tool | Best For | Pricing Model | Free Option |

|---|---|---|---|

| Opstream | Cross-system approvals and policy-gated robot dispatch | Custom quote | None public |

| MOV.AI Robotics Engine Platform | OEMs and SIs building AMRs on ROS with simulation and fleet tools | Custom quote | Developer IDE announced free, see PR Newswire |

| Vecna Robotics Pivotal | Pallet and case workflows in warehouses and 3PLs | Subscription, RaaS style with SLAs | None public |

| FLOW Core by OMRON | Factory fleets standardized on OMRON AMRs | Custom quote | None public |

Autonomous Robotics Workflow Platform Comparison: Key Features at a Glance

| Tool | Fleet Orchestration | Simulation | Analytics |

|---|---|---|---|

| Opstream | Policy-gated task triggers across systems | N/A | Workflow audit and policy logs |

| MOV.AI | Task, traffic, and fleet control with open APIs | Integrated 3D physics and sensor sim | Platform dashboards and debugging tools |

| Vecna Pivotal | Human and robot task orchestration with WMS integration | Use-case simulation is part of deployment programs | Pivotal Insights and Command Center telemetry |

| FLOW Core by OMRON | Centralized job assignment and traffic rules | Fleet Simulator reported in public news | FLOW iQ heat maps and performance stats |

Autonomous Robotics Workflow Deployment Options

| Tool | Cloud API | On-Premise | Air-Gapped | Integration Complexity |

|---|---|---|---|---|

| Opstream | Yes, SaaS product category | Not publicly documented | Not publicly documented | Low to medium |

| MOV.AI | API-driven, deployment varies by customer | Yes, for robot software | Possible in industrial networks | Medium, ROS integrations plus enterprise IT |

| Vecna Pivotal | Yes, remote monitoring and updates | Site components for WMS required | Often requested in warehouses | Medium, depends on WMS connectors |

| FLOW Core by OMRON | API options reported | Yes, fleet server appliance | Common for factories | Medium, simulator helps de-risk |

Autonomous Robotics Workflow Strategic Decision Framework

| Critical Question | Why It Matters | What to Evaluate | Red Flags |

|---|---|---|---|

| Do we need multi-vendor fleet orchestration? | Many facilities run mixed vendors | Interoperability path, MassRobotics and VDA 5050 support | Locked to one brand with no roadmap |

| How will we simulate jobs before go-live? | Simulation avoids aisle deadlocks | Built-in or partner simulation, map import | No simulation, rely on live floor |

| Who solves edge cases at 2 a.m.? | Uptime and incident recovery drive ROI | Remote monitoring, teleoperation, SLA response | "Best effort" support without clear SLAs |

| What governs dispatch, budgets, and policy? | Compliance gates often delay robot work | Cross-system workflow engine that triggers when compliant | Email approvals outside system |

Autonomous Robotics Workflow Solutions Comparison: Pricing & Capabilities Overview

| Organization Size | Recommended Setup | Monthly Cost | Annual Investment |

|---|---|---|---|

| Mid-market warehouse | Vecna Pivotal for pallet or case flow, or FLOW Core if standardized on OMRON | Not publicly available | Not publicly available |

| Enterprise manufacturer | FLOW Core with Fleet Simulator, Opstream for policy-gated dispatch | Not publicly available | Not publicly available |

| Robotics OEM or SI | MOV.AI for ROS dev and simulation, pilot on customer floor | Not publicly available | Not publicly available |

Problems & Solutions

-

Problem: Case picking productivity stalls when robots and people fight for aisle time.

Solution with Vecna Pivotal: CaseFlow uses Pivotal to automate most travel, dynamically assigns zones to pickers, and integrates to leading WMS systems, with media reports citing doubled worker throughput in pilots. (Business Wire product launch) -

Problem: New AMR builds take months, field changes break brittle code.

Solution with MOV.AI: Visual ROS IDE, 3D simulation, and packaged autonomy blocks shorten bring-up and let teams test pallet pickup and navigation changes off-line before deployment, per public release notes and industry newswires. (PR Newswire IDE launch) -

Problem: Go-live reveals bottlenecks in wireless coverage and map rules.

Solution with FLOW Core: Teams use the Fleet Simulator and analytics to surface heat maps, job stats, and battery health to tune routes and traffic logic before rollout, as described in public news items from regional channels and distributors. (Context on simulator in regional posts summarized by distributors and media roundups) -

Problem: Robots get dispatched before vendor risk, budget, or contract gates are cleared, causing rework.

Solution with Opstream: Reviewers report significant reductions in manual follow-ups and faster approvals as workflows run themselves and nudge the right stakeholders, which keeps WMS tasks and robot jobs policy-compliant. (G2 user reviews)

The Bottom Line on Autonomous Robotics Workflow Platforms

Robots do not fail in isolation - orchestration does. In 2026, the difference between a scalable AMR deployment and a stranded fleet is whether coordination, simulation, and recovery are first-class capabilities rather than bolt-ons layered after go-live.

If your priority is live warehouse throughput with people and robots sharing space, platforms like Vecna Pivotal stand out by tightly coupling WMS tasking, human direction, and 24x7 remote intervention. That human-in-the-loop orchestration is where most ROI models either hold or leak. If you are building or deeply customizing AMRs, MOV.AI offers one of the strongest combinations of ROS-based development, simulation, and enterprise controls, but you should budget explicitly for ROS expertise and CI discipline. For factory environments standardized on a single vendor, FLOW Core by OMRON delivers fast time to value through native simulation, traffic control, and analytics tightly bound to the fleet.

Across all setups, policy and coordination gaps increasingly sit above the robot layer. Tools like Opstream matter because they decide when robots should work at all - only after budgets, vendor risk, and approvals clear automatically. Market signals support the urgency: AMR adoption continues to expand despite regional volatility, and industrial robot density keeps rising, which raises the coordination burden, not lowers it. The teams that win in 2026 treat orchestration software as mission-critical infrastructure. Simulate before you deploy, standardize task APIs early, and invest in recovery paths for the inevitable edge cases that only appear at 2 a.m. during peak shift.